Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Design and Analysis of Innovative Machine to make Bio Cups and Plates from Agricultural Waste

Authors: Hariharan V, R. Arulraj

DOI Link: https://doi.org/10.22214/ijraset.2023.53615

Certificate: View Certificate

Abstract

With the growing popularity of sustainability, many companies have begun using environmentally friendly materials. This is particularly significant for the disposable tableware market. one hundred billion single-use cups are sent to landfills annually in the our country. Their production, usage, and disposal cause deforestation, pollution, and human health problems. Attempts have been made to produce more environmentally friendly tableware, however, these options are frequently not economically or logistically viable. From This innovative design of machine , we can make a bio degradable cups and plates from different agricultural waste materials like banana stem, rice bran, rice husk, paddy straw, wheat bran, wheat grass, tender coconut shell, coir fiber and so on. Based on the raw materials available on their locations we can able to make a sustainable single use cups from the available agricultural waste materials. After utilization of this single use tea cups, Again by crushing and dissolved in water, we can provide these as a cattle feed. This project strived to develop a single-use cup that meets the market need while remaining biodegradable and sustainably sourced. The designing of the innovative machine is carried out by using the software PTC creo 8.0.And the analysis is carried out by solidworks simulation.

Introduction

I. INTRODUCTION

With the growing popularity of sustainability, many companies have begun using environmentally friendly materials. This is particularly significant for the disposable tableware market. Most plastic utensils, paper plates, and styro foam carrying containers are used once for a few hours and then left in a landfill for hundreds of years before they degrade. Efforts have been made in recent years to create single-use tableware that biodegrades in a shorter time frame. Despite their widespread use, single-use cups have not received an environmentally conscious upgrade. This project focused on creating a fully biodegradable single-use cup. The final product consists of agar, hemp, and other natural ingredients coated with wax. This report presents the production process of the product as well as an overview of the engineering design that utilized an axiomatic design process to develop the product. Additionally, a series of experimental tests are outlined that demonstrate that the product has potential to become comparable to other similar products on the market. Furthermore, a financial and market analysis was conducted to display the single-use cup industry and a biodegradable cup’s place in it. The creation of this fully biodegradable cup makes further strides in the ever-present goal of developing sustainable single-use tableware and has applications beyond the initial goal.

A. Objective

Our aim to design a machine, where we can able to make a single use biodegradable cups and plates based on the raw materials available nearer to the manufacturers. While the raw materials are the agricultural waste, so based on the nature we can utilize the available raw materials like rice husk, rice bran, banana stem, paddy straw, wheat bran, wheat grass, tender coconut shell, coir fiber and so on. According to the raw material we can change the mode of operation in our device. By this innovative device we can utilize the agricultural waste to the maximum. And also we get the alternative to the plastic cups. By so we can save the environment.

II. LITERATURE REVIEW

With the growing popularity of sustainability, many companies have begun using environmentally friendly materials. This is particularly significant for the disposable tableware market. Most plastic utensils, paper plates, and styro foam carrying containers are used once for a few hours and then left in a landfill for hundreds of years before they degrade. Efforts have been made in recent years to create single-use tableware that biodegrades in a shorter time frame. Despite their widespread use, single-use cups have not received an environmentally conscious upgrade. (Professor Sarah Wodin-Schwartz PhD P.E. & Professor Walter Towner PhD , Department of Mechanical Engineering and Foisie Business School May 2019).

When disposable plastic straws are banned, customers will need to use biodegradable straws provided by the tea shop or rely on bringing their own reusable straws. Extensive research has been conducted on the topic of eco-friendly straws that are biodegradable, recyclable, and/or reusable (Salomao, 2020; Yang et al., 2019).

Paper cups are created from the fresh pulp of lumber, requiring the destruction of trees in the production process (Starbucks, 2018). 20 million trees are cut down annually for the production of paper cups, as most cups are made from virgin paper (Steely’s Drinkware, 2013). Despite being made out of a naturally biodegradable material, paper cups continue to harm the environment in the post usage stage. For every four paper cups discarded, one pound of CO2 emissions is created, and in the U.S. alone, 58 billion paper cups are thrown away annually (Steely’s Drinkware, 2013). In order to remain waterproof, the cups are lined with polyethylene, a type of plastic that is not biodegradable or compostable. This means that the entire cup is unable to be composted or broken down by the environment. Additionally, because of their plastic coating and the fact that they are less resilient to foreign contaminants, paper cups are often unable to be recycled (Steely’s Drinkware, 2013).

In the US alone, 25 billion styrofoam cups are used and discarded annually (Steely’s Drinkware, n.d.). Styrofoam cups are made from a non-biodegradable, petroleum based plastic that cannot be recycled and is estimated to last between 500 and one million years before fully breaking down depending on the external conditions (Le Guern, 2018). Additionally, polystyrene, the main component of styrofoam, leaks an endocrine disruptor called leaches styrene when it comes into contact with oily or heated materials. This disruptor can cause long term health problems affecting the reproductive and nervous systems of its users (Le Guern, 2018). Significant migration of this chemical occurs any time Styrofoam cups are used for hot liquids. Furthermore, approximately 90 toxic and hazardous chemicals are produced when cups are incinerated by disposal companies (Steely’s Drinkware, n.d.). Despite this, Styrofoam continues to be a mainstream material choice for single use cups.

Plastic cups, while less destructive to human health than their styrofoam counterpart, are the most common type of single-use cup and still have many known issues associated with them. As of 2018, the world population uses 500 billion plastic cups a year (Fact, 2018). Single use plastics are divided into two categories, plastics that are malleable when reheated, called thermoplastics and plastics that once set with heat, remain rigid, called thermosets (Giacovelli,2018). Neither thermoplastics nor thermosets break down naturally in the environment or with commercial composting. About 80% of plastic products ever produced are discarded in the environment (Giacovelli, 2018). This results in plastic occupying 30% of all landfill space (Steely’s Drinkware, 2013). Plastic cups are sometimes advertised as being recyclable or even compostable, but due to human error, this frequently does not happen (Reality, 2015). In fact, only about 9% of plastic products get recycled (Giacovelli, 2018). A description of the difference between compostable and biodegradable products is shown in Figure 2. Despite these obvious problems, the versatility and low cost of plastic perpetuates its reliance in comparison to eco-friendly alternatives. Plastics tend to be “lightweight, hygienic and resistant” over long periods of time, making them favorable for food storage and other packaging needs (Giacovelli, 2018). These properties become especially important for containing and transporting liquids. A cup needs to be able to preserve liquids for an extended period of time, protect contents from outside contaminants, be transportable, and display information, making single-use plastic cups the mainstay of the disposable cup market (Harvey, 2018).

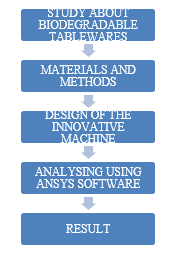

III. METHODOLOGY

IV. STUDY ABOUT BIODEGRADABLE TABLEWARE

Disposable plate and cups has emerged as a better alternative to plastics across the globe and Indians have been early adopters of biodegradable products. All kinds of plant biomass material such as bagasse, rice husk, coconut coir etc. are being utilized for producing eco-friendly cutlery, tableware and packaging products that could see a surge in usage in the coming decade.

Rice husk is a surprisingly strong material that can withstand significant wear and tear and has a long life. Rice husk tableware is one of the most durable forms of disposable plate and cups that can withstand temperatures of more than 100ºC without getting damaged. This reusable tableware has a smooth glossy covering that is 100% natural and derived from the wax present in rice husks.

Rice husk plates is highly friendly, high performing, and cost-effective products manufacturing using top-quality materials and industry-leading technology. Great to hold and use and no unpleasant feeling of wooden single use tableware in your mouth. Ditch the single use plastic and bio plastic and reuse the natural sustainable alternative. Give a gift that has a positive effect, take to work, use at the deli takeout, switch from plastic at the refectory and avoid single use surcharges too.

A. Advantages

- Reduces Pollution: Instead of burning the agricultural waste which releases harmful substances into the air, it is revived into new products.

- Chemical Free: Tableware made from agricultural waste are completely earth friendly. These are not treated with any chemical or inks.

- Conserves Valuable Natural Resources: By repurposing agriculture waste into new resources, it helps to conserve natural resources such as oil, metal, wood, and water.

- Great to hold and use: no unpleasant feeling of wooden single use tableware in your mouth. Ditch the single use plastic and bio plastic and reuse the natural sustainable alternative.

V. DESIGN BY USING CREO 8.0

Creo is 3D CAD software that helps you build better products faster. With tools that speed innovation, enhance collaboration, support design reuse, and replace assumptions with facts. It is the 3D CAD solution that helps you accelerate product innovation so you can build better products faster. Easy-to-learn Creo seamlessly takes you from the earliest phases of product design to manufacturing and beyond

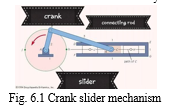

VI. WORKING PRINCIPLE

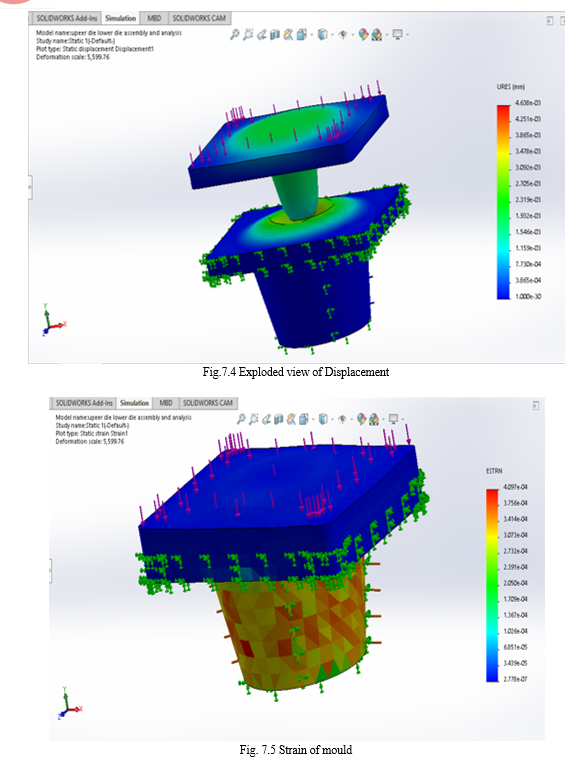

Slider-Crank mechanism, arrangement of mechanical parts designed to convert straight-line motion to rotary motion, as in a reciprocating piston engine, or to convert rotary motion to straight-line motion, as in a reciprocating piston pump. The basic nature of the mechanism and the relative motion of the parts can best be described with the aid of the accompanying figure, in which the moving parts are lightly shaded. The darkly shaded part 1, the fixed frame or block of the pump or engine, contains a cylinder, depicted in cross section by its walls DE and FG, in which the piston, part 4, slides back and forth. The small circle at A represents the main crankshaft bearing, which is also in part 1. The crankshaft, part 2, is shown as a straight member extending from the main bearing at A to the crankpin bearing at B, which connects it to the connecting rod, part 3. The connecting rod is shown as a straight member extending from the crankpin bearing at B to the wristpin bearing at C, which connects it to the piston, part 4, which is shown as a rectangle. The three bearings shown as circles at A, B, and C permit the connected members to rotate freely with respect to one another. The path of B is a circle of radius AB; when B is at point h the piston will be in position H, and when B is at point j the piston will be in position J. On a gasoline engine, the head end of the cylinder (where the explosion of the gasoline-air mixture takes place) is at EG; the pressure produced by the explosion will push the piston from position H to position J; return motion from J to H will require the rotational energy of a flywheel attached to the crankshaft and rotating about a bearing collinear with bearing A. On a reciprocating piston pump the crankshaft would be driven by a motor.

A. Working Procedure

The raw materials where the agricultural waste is collected from the farming after harvesting, Based on the type of raw material , the procedure of making cup will be vary.

If the raw material like rice bran, rice husk, wheat bran , they are in the powder structure, so we have to mix with the binding materials like maida and water in a right proportion.

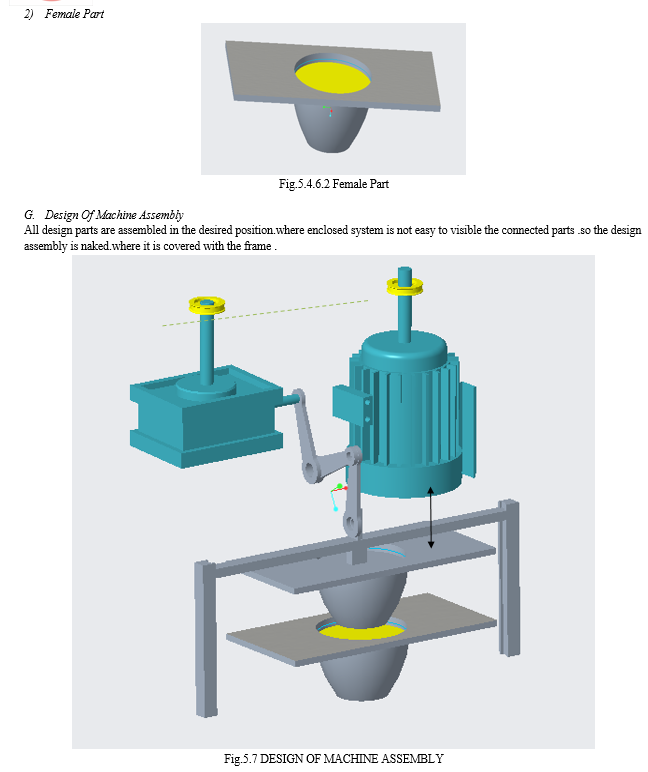

After mixing take a required amount of mixed rice bran and place in the female mould part.

When the motor starts running it connected to the gear box through pulley ,

whereas it makes the male mould part to mate inside the female part through the connecting rod.

Where it works on the principle of the crank slider mechanism.

After mating of the mould the motor will stop by using the timer .

And the heating coil is attached to the upper and lower die and the heater switch should be in the ON position.

The temperature have to be around 70? to 80? c.

The process of heating and pressing will convert the raw material into the required shape like tea cups .

The holding time is around 30 seconds. After that again the motor starts run and opens the mould of upper and lower die.

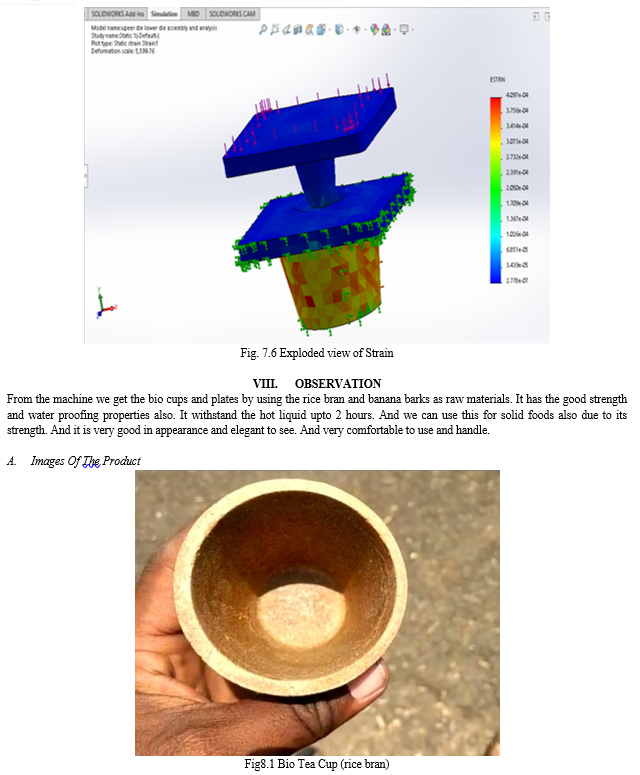

Finally we can get the biocups from the agricultural waste.

The bio cups withstand the hot liquid upto 2 hours from leaking.

For fiber like material such as banana barks , we can use as it is after get dried.

And according to the properties of the raw material we have to mix with the binder in correct proportion and the working of the machine remains same.

VII. ANALYSIS

A. Stress Analysis

Stress–strain analysis (or stress analysis) is an engineering discipline that uses many methods to determine the stresses and strains in materials and structures subjected to forces. In continuum mechanics, stress is a physical quantity that expresses the internal forces that neighboring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material.

In simple terms we can define stress as the force of resistance per unit area, offered by a body against deformation. Stress is the ratio of force over area (S =R/A, where S is the stress, R is the internal resisting force and A is the cross-sectional area). Strain is the ratio of change in length to the original length, when a given body is subjected to some external force .

Typically, the starting point for stress analysis are a geometrical description of the structure, the properties of the materials used for its parts, how the parts are joined, and the maximum or typical forces that are expected to be applied to the structure. The output data is typically a quantitative description of how the applied forces spread throughout the structure, resulting in stresses, strains and the deflections of the entire structure and each component of that structure. The analysis may consider forces that vary with time, such as engine vibrations or the load of moving vehicles. In that case, the stresses and deformations will also be functions of time and space.

In engineering, stress analysis is often a tool rather than a goal in itself; the ultimate goal being the design of structures and artifacts that can withstand a specified load, using the minimum amount of material or that satisfies some other optimality criterion.

Stress analysis may be performed through classical mathematical techniques, analytic mathematical modelling or computational simulation, experimental testing, or a combination of methods.

The term stress analysis is used throughout this article for the sake of brevity, but it should be understood that the strains, and deflections of structures are of equal importance and in fact, an analysis of a structure may begin with the calculation of deflections or strains and end with calculation of the stresses.

B. Analysis Of Cup Mould Using Solidworks Simulation

C. Result

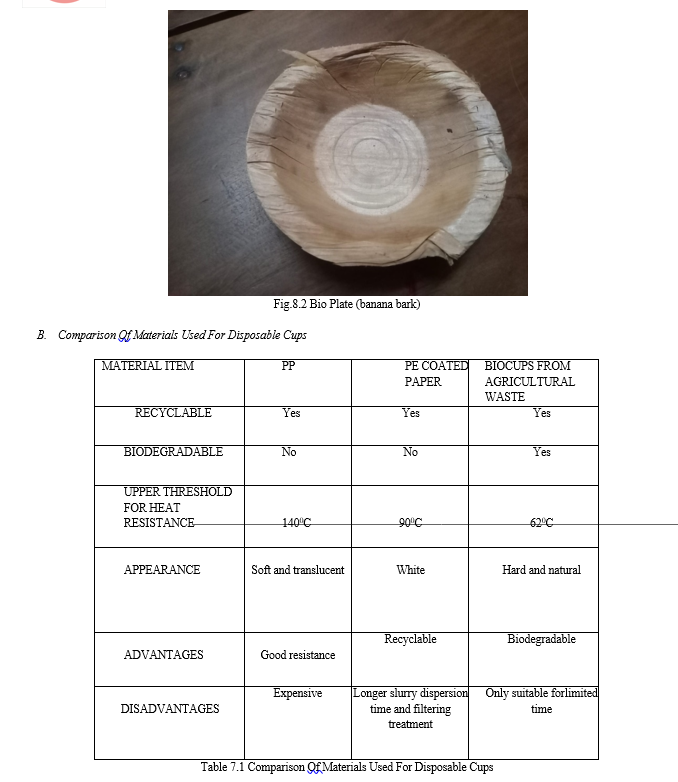

For making the effective use of agricultural waste, we have planned to make a bio cups and plates. For that there is no machine is available .To make a value products from the agriculture waste we try to make bio cups trough mould manually. To improve the technology and get the result in very useful way, we have designed a machine .The machine design is done by using the creo 8.0 software . And the stress analysis for the machine mould is also done by using the solidworks simulation . The result is feasible and the material is chosen as cast carbon steel.

The Maximum stress obtained = 1.559 e+8N/m2

The yield stress =2.482 e+8 N/m2

Maximum Stress obtained < Yield stress

According to Maximum principal stress theory , The design and the material is safe.

References

[1] L. B.-P. N.A. Peppas, Encyclopedia of Materials: Science and Technology, 2001. [2] Niir Project Consultancy Services, “Entrepreneur India,” [Online]. Available: https://www.entrepreneurindia.co/Document/Download/Biodegradable%20and%20Compostable%20Disposable%20Cups%20and%20Plates%20from%20Sugarcane%20Bagasse%20and%20Wheat%20Straw.-391757-.pdf. [3] P. I. C. Ltd, “Eco-Papercup,” [Online]. Available: http://www.eco-papercups.com/sale-11873162-corn-based-sugarcane-compostable-paper-cups-tree-free-custom-flexo-printing.html. [4] Amazon Sugarcane Cup,” [Online]. Available: https://www.amazon.com/World-Centric-Compostable-Bagasse Package/dp/B07JN2FBSX/ref=sr_1_3?dchild=1&keywords=sugarcane+bagasse+drinking+cup&qid=1587406298&sr=8-3. [5] J. Nikodinovic-Runic, “Sciencedirect Sugarcane Bagasse,” [Online]. Available: https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/bagasse. [6] E. Royte, “Smithsonian Magazine,” Corn Plastic to the Rescue, 2006. [7] E. V. Sperling, Energy Procedia, SciVerse ScienceDirect, 2012. [8] C. D. 4. Ziyue He, “Design Life-Cycle,” 11th March 2016. [Online]. Available: http://www.designlife-cycle.com/biodegradable-paper-cups. [9] Lei, S., and Stacey Lei. (2020). Repurchase Behavior of College Students in Boba Tea Shops: A Review of Literature. College Student Journal, 53(4), 465-473. [10] Gao, A. L., & Wan, Y. (2022). Life cycle assessment of environmental impact of disposable drinking straws: A trade-off analysis with marine litter in the United States. Science of The Total Environment, 817, 153016. doi: https://doi.org/10.1016/j.scitotenv.2022.153016.

Copyright

Copyright © 2023 Hariharan V, R. Arulraj. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET53615

Publish Date : 2023-06-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online